Anyone See Fake Britain Gu10 Lamps ..well here is how we designed and make ours. (November 24th, 2015)

(2019/9/16)

10

As Operations Manager and a Lighting professional I like many watched in Horror the "Fake Britain" Episode showing ultra dangerous GU10 lamps on sale in the UK.

I Understand we all wish to reduce energy and what way better. Take those 50W spotlights out and put in a new ECo LED version.

As operation Director of Auraled Lighting in China?www.auraledlighting.comI am duty bound to aim for Quality in every aspect of manufacture, safety being a paramount concern.

Fact is also as a Director of a UK company?www.auraled.co.ukshould a death occur at the hands of one of our fittings or lamps I with the other Directors are Liable for prosecution. So I take Manufacturing in every aspect ultra seriously.

I live in China and have done 9years, We manufacture and I aid with the design with our products, I am not new to this field.

Going back 4-5years ago I recollect a client asking me to visit another factory as he wished to purchase some product from them. Unbeknown to me as I visited to see some linear product they?were assembling Gu10 lamps excactly as seen on this show. I remember walking in, seeing the production and walking straight back out.

Sales following asking "why!!". See I have seen it all living in China for 9years and take ultimate pride in manufacture. I have seen these things being slapped together a pleanty in small Sheds!!! ?I impart all that experience How not to do upon our team and all we work with.

So here firstly is how I came up with the Idea for our PRO GU10.....

?https://www.linkedin.com/pulse/why-do-most-led-gu10-fail-impress-me-barrie-vesty?trk=mp-reader-card

Now I am going to do something exceptional and show you how we designed the product to be "safe" and "comply" with Laws. We have tested them to all European laws.

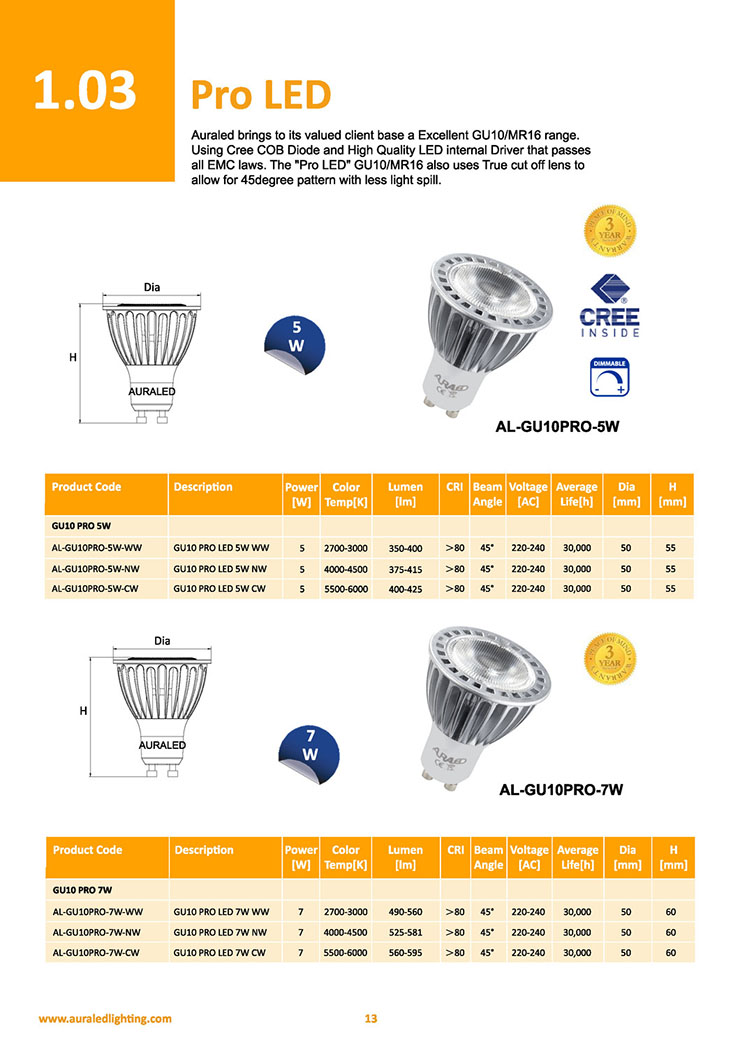

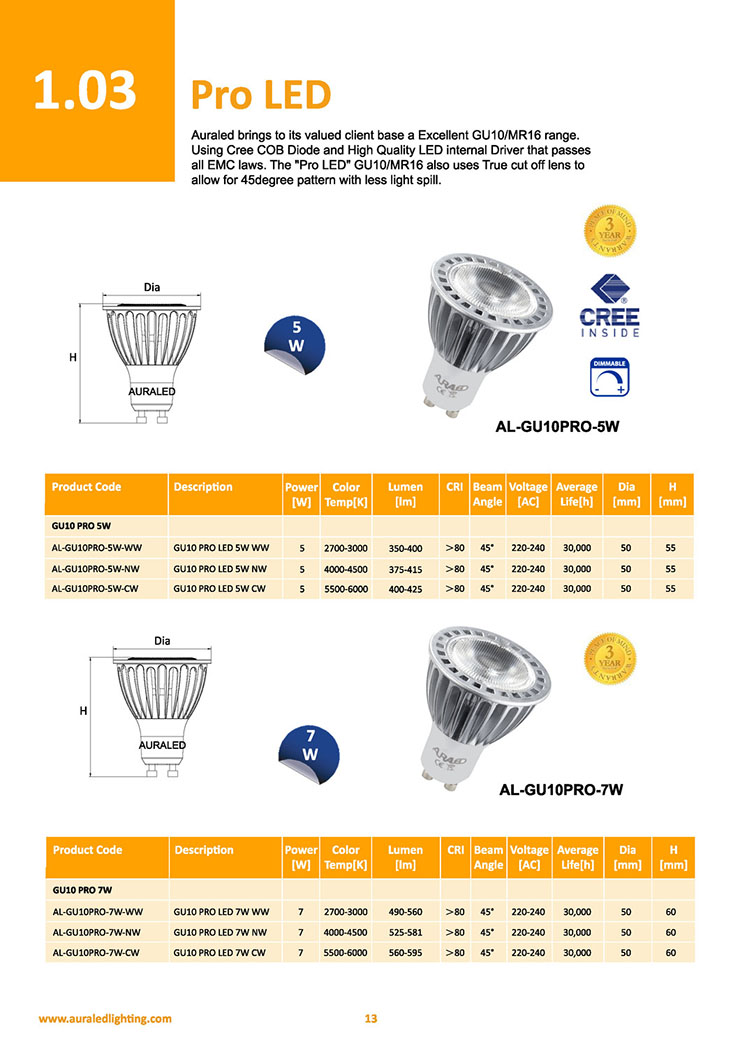

Firstly 70% of producers are just buying common parts and slapping together, many traders exist in that business. Our Pro GU10 was designed by 3D CAD considering every aspect.

Firstly we do use a Diecast Heatsink but access to the inside is from two very small screws that require a special screwdriver to open. Removing these screws allows the lens to then Fall out. This is the ONLY way to access the Diode point or Driver, it is engineered forwards into one unit, no screw threads between base and casting. Screw threads can easily break or tear cables and those cables can touch housings.

See that was a Major NO NO on the Fake Britain show...screw together parts. LED driver just falling out.

The first step to getting inside our lamp is to use a special screwdriver to remove the two small screws as you can see on the picture.

Once the two small screws have been removed by a special screwdriver the Lens is removed and Lamp semi open. Our Cree Diode PCB COB has two Layers with Circuits, no cables that can come loose. The power is fed up the two outside bolts?into the Top PCB that is soldered to the Diode PCB Covered using a Special ultrasound applied clear glue.

I will explain how we make risk of shorting very minimal indeed on the bolts. Basically the Plastic?Base has two Plastic Legs that sit right behind the PCB, these Bolts go through the PCB then inside this through the casting.

Taking the two Bolts?out now allows the Cree PCB to be removed and also the housing from the Base of the Lamp. These screws enter a plastic channel from the top?where they make the connection from the driver. These Plastic legs travel right upto the back of the PCB, both parts being sealed circuit FR4 PCBs.

You can see from the above How even the Platform for the Cree diode has been engineered into the casting (apologies for the heat transfer cement) The + in the cating is only for assembly worker reference.

Now for the Driver. firstly the Driver is our own engineered driver that passes ALL European laws on EMC/EMI. It is firstly soldered to the Inside Pins on the base and Then Potted with PVC. This makes it impossible for the Driver to "fall out" of the Plastic base. Two screw terminals are placed inside each plastic leg, driver cables fixed and the main screws screw down into these. This then becomes Totally safe by locking the casting on top that is important for heat sinking.

The cables cannot move upwards as they are set in place. The bolts then lock everything together and form the connection between driver and diode.

The Heat Sink sits over the two Stems travel up inside much larger holes and are fixed by the two bolts that carry current.

This makes the risk of any shorting ultra Minimal. But how do we test against this also..leads on to assembly and testing.

For the Manufacturing aspect: Firstly ALL of these are manufactured in our Factory, they are deigned by US. We do not travel to a show and say "hey make these!"....

When we run a production each lamp is tested on the line for any Leakage. Occasionally we will find some but the idea is that we minimalise the risks of shorting and should ?any have leakage we can effectively remove from packaging.

After this next stage we conduct Burn tests in our Burn room set up for these, again to age test lamps to ensure these are dry upon despatch. These then go onto Switch Cycle testing.

We also High pot test some from each batch, this means placing a very high voltage into the lamp to see if a shortage occurs.

Here is However My Top Tips?for ANYONE who has Halogen Glass Gu10 Lamps and is about to make a purchase of LED replacements:

1) BUY LOCAL from a Reputable Electrical Wholesaler, ask THEM advice about the product they have had no issues with.

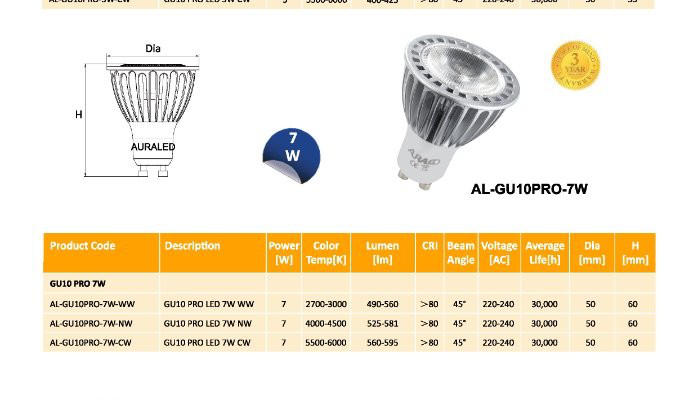

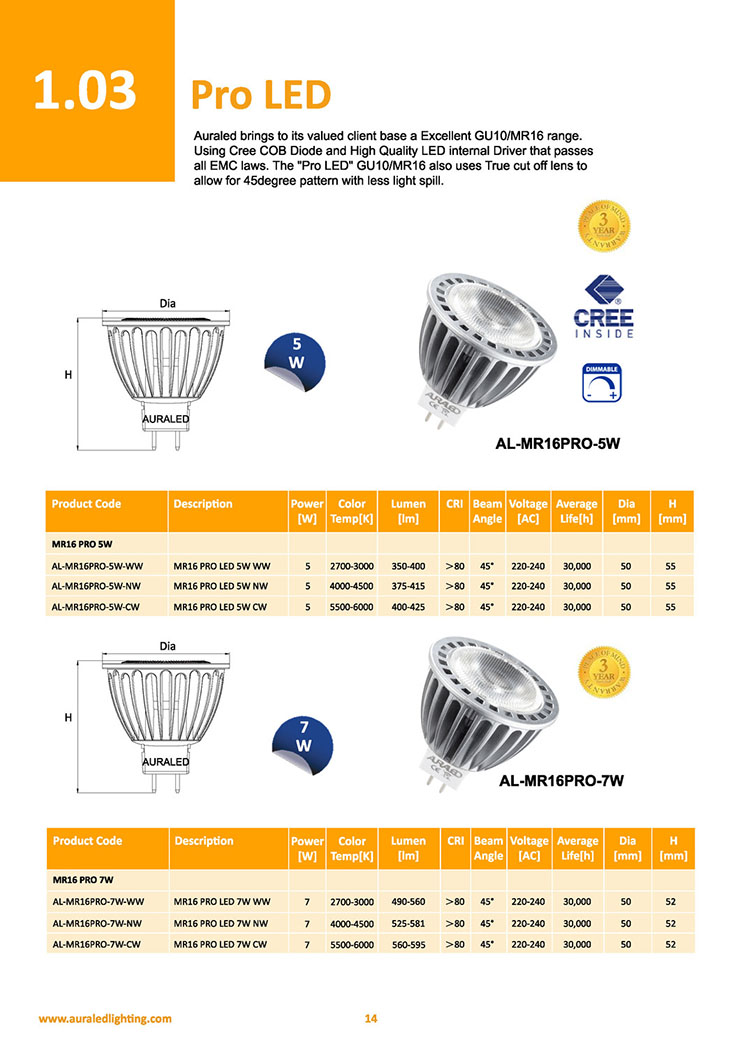

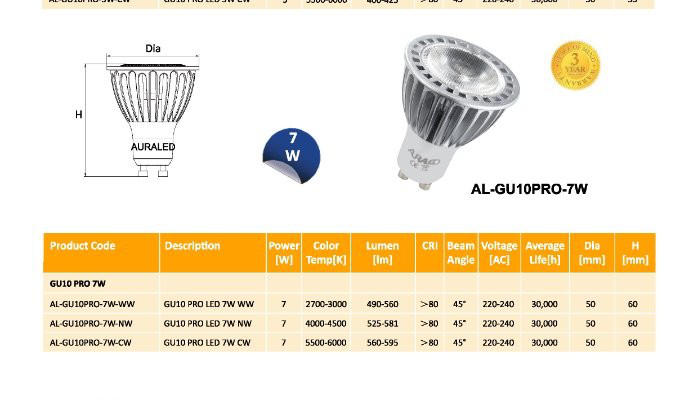

2) If you have Old 50W Gu10 then NEW LED versions are Not about Wattage But lumens!! You old lamp was 550-600Lm, so look for around the same. Our Pro GU10 7W is 550Lm using very high Quality Cree COB.

3) New LED versions ARE NOT like Glass Halogen lamps. Obviously you could not touch a Halogen lamp when on so you will turn off the circuit to change. But in the instance where bye your old Halogen lamps have failed and you replace with New LED versions ensure you switch the circuit off first.

4) If you have replaced your Lamp, placed back in situe and switched on with a breaker blowing then switch off, remove all lamps and send back to the manufacturer for testing. This is an obvious sign of shorting (leakage).

5) Do not Buy LED GU10 lamps with Open PCBs at the front at any cost. These are Lethal. If you can touch the diodes and see the cables to the PCB STAY CLEAR!!!

6) A Bargain is Not a Bargain in LED!! We use Cree COB and we MUST use Aluminium Heat Sink to dissipate the heat...LEDs fade with heat. A Good Quality LED??GU10 will last for many years and should cost you around $14 But they will pay themselves back 20times over.

7) Wow a Big one EMI..(Electro Magnetic Interference)! If you install GU10s and your radio will not work, take them out and send them back with a note saying "garbage!". Quality MFRd LED lamps use a high Quality LED driver that passes EMC/EMI and will not cause this.

My few?points to mention is Like anything companies get some "slip through the net" we have seen massive recalls by some industry players over the last 4years on products.

We also are not immune to the odd few slipping?through the net but we have a viable network to minimalise risk to clients. See we do not supply "direct to your Home" from our Manufacturing side. We work with a network of credible distributors who value the diligence we pay upon manufacture.

I guess the others who sell Gu10s in the UK will not be taking them apart and posting how they are manufactured or the component used?. Probably busy banging out this months cheaper deal......Says a lot about our industry.

So now I show our underwear and How we make our Pro Gu10...available from ANY Excellent wholesaler in the UK and France. If your a wholesaler reading contact Auraled UK for excellent prices. If Your a distributor in another nation reading speak to us we can design for you.

Cover image: